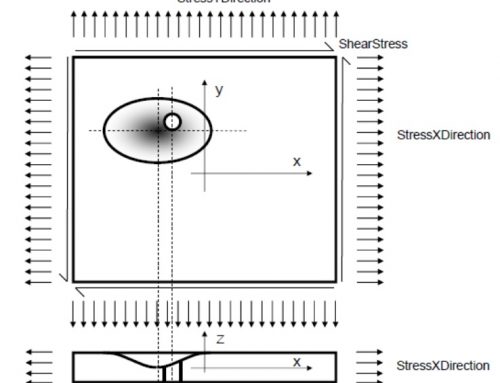

In a project for the aircraft industry, ALE has optimised the fatigue life of finger doubler repairs. External repair doublers are used to repair damaged aircraft skin panels. For the particular case of fibre-metal laminate skin, fatigue cracks occur in the skin underneath the repair doubler. This leads to inspection problems, which can be avoided if finger doubler repairs are used.

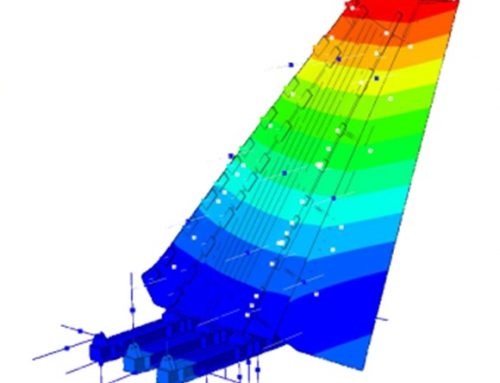

Fatigue life is directly related to peak stress. Therefore peak stress minimisation was used as the objective for the optimisation process. Design parameters included, among others, doubler thickness, finger width and number of rivet rows. Within the predefined design space 121,400 different designs were possible. This clearly illustrates the need for a sophisticated approach to find the optimal design.

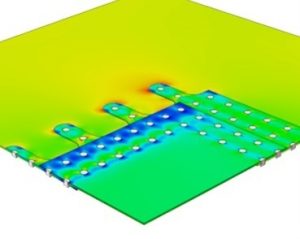

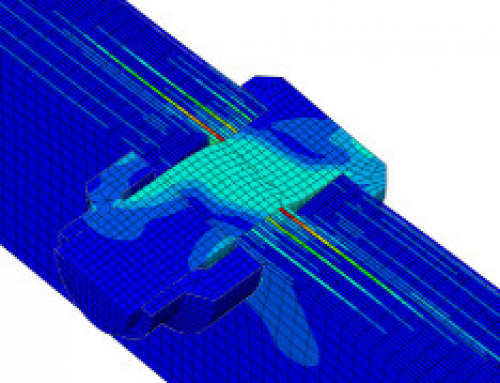

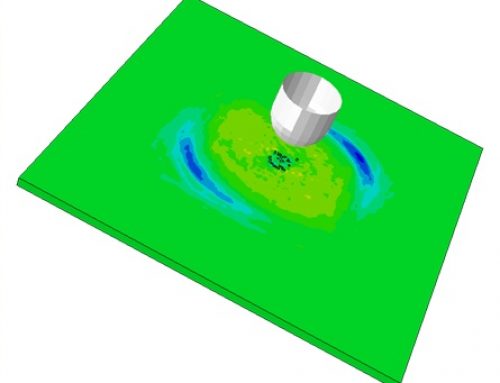

Finite Element (FE) analysis was used to evaluate peak stress for a given design. The FE model is set-up parametrically, such that the pre-processing, analysis and post-processing is fully automated, based on only the design parameters. The FE model is coupled to optimisation software in order to find the best design. The optimisation software explores the design space and determines the best search direction by prescribing the design parameters and steering the parametric FE model. Obviously, the parametric FE model has to be extremely robust to avoid that the optimisation cannot be performed properly.

From the optimisation a finger doubler design was found, not only avoiding the inspection problems of the reference design, but also having an improved fatigue life and reduced mass.