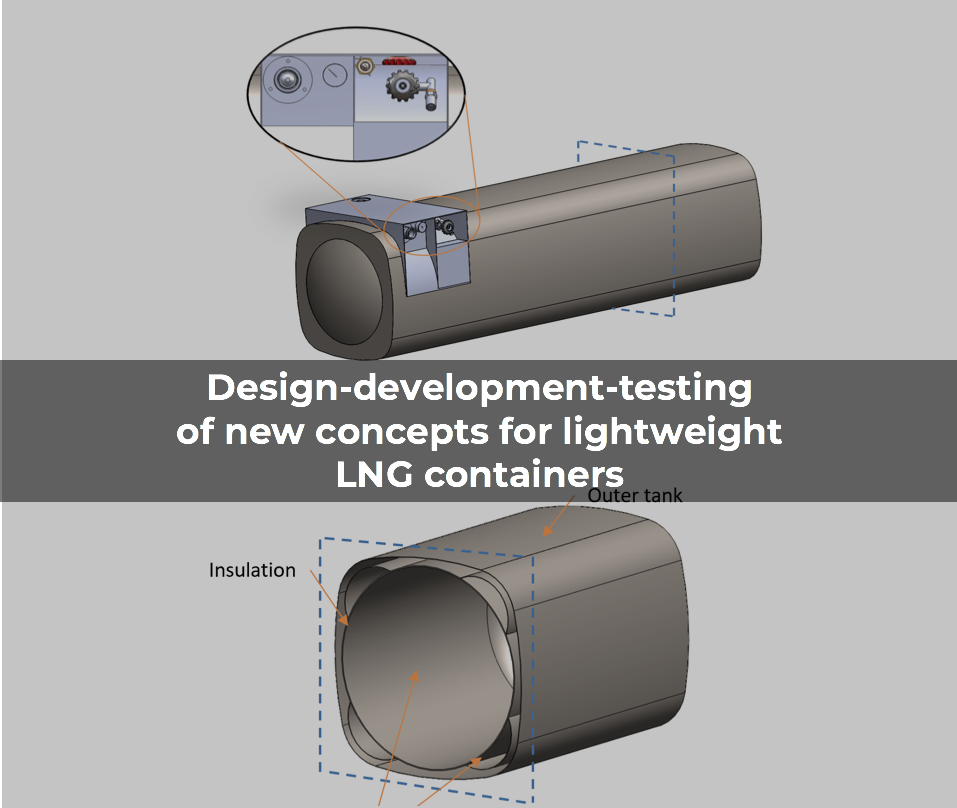

ALE participate in different projects funded by the EU in relation with the design and development of new concepts for lightweight LNG containers. With the expertise in the field of lightweight constructions and especially in the experience in the field of composite pressure vessels, development and processes of all kinds of PU elastomers and foams, ALE participate in the development of patented concepts as well as developing process for new materials, since the manufacturing and testing of the foam material and the elastomeric crust, from sample level, to the full size test of the foamed vessel.

LNG PILOTS is a 4-year project funded by the EU through the Interreg Va (Netherlands-Germany) framework. The project aims to develop and test strategies and innovative solutions for the distribution and application of LNG and bio-LNG in the transport and industry sectors in the Dutch-German border area.

The objective of this project is developing and testing a high volume LNG storage tank for on-board storage of LNG. This new tank technology will increase the capacity of the LNG tank and by consequence, extend the range of the truck.

ALE is been developing and tested a new design denominated the multibubble concept , providing extra storage capacity. The manufacturing of the of the prototype is being done by Cryovat.

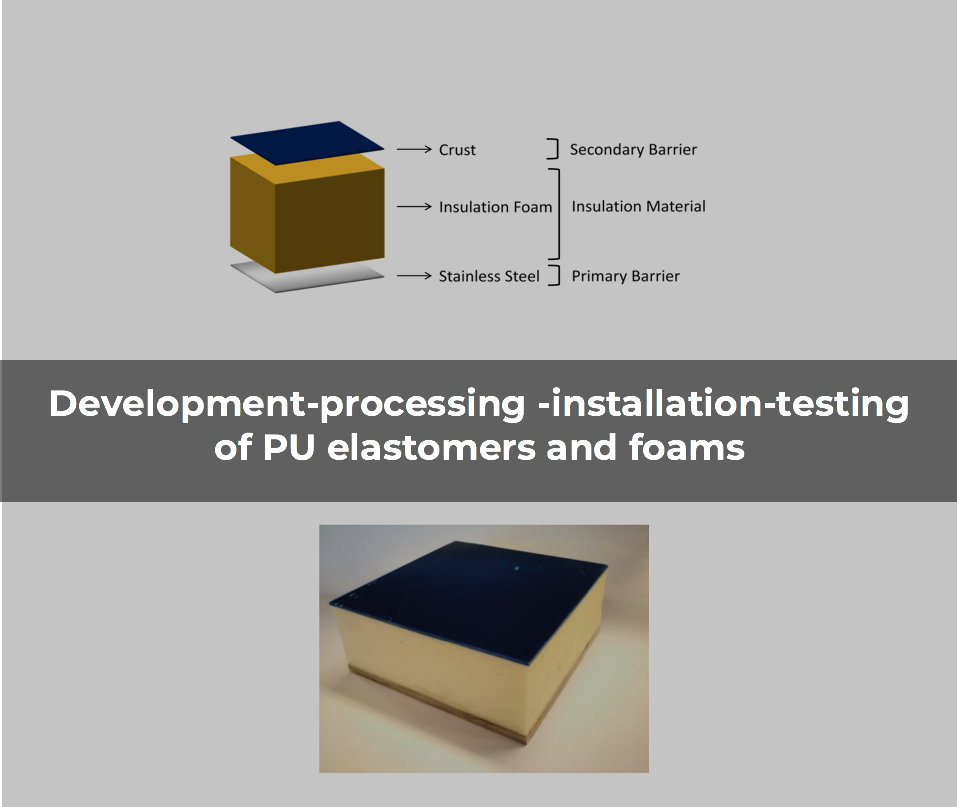

Within the EU-funded LNG PITCH4 project, ALE participates in the developing and testing of new liquefied natural gas (LNG) tank for seagoing vessels. ALE was responsible of the development and installation of the thermal insulation of a 12m3 with an innovative PU foam solution with an external elastomeric crust.

The complete developing process included the manufacturing and testing of the foam material and the elastomeric crust, ranging from sample level, tested according to the correspondent norms and standards (ASTM and ISO), to the full size test of the foamed vessel.

With our expertise in fibre-reinforced polymers and light metals (and combinations of these two), we can offer ready-to-use solutions where weight, strength and maintenance are important.

ALE Delft works in different markets, ranging from aerospace specialty products to fibre research and testing. We are constantly expanding our knowledge to offer our clients the best possible solution.

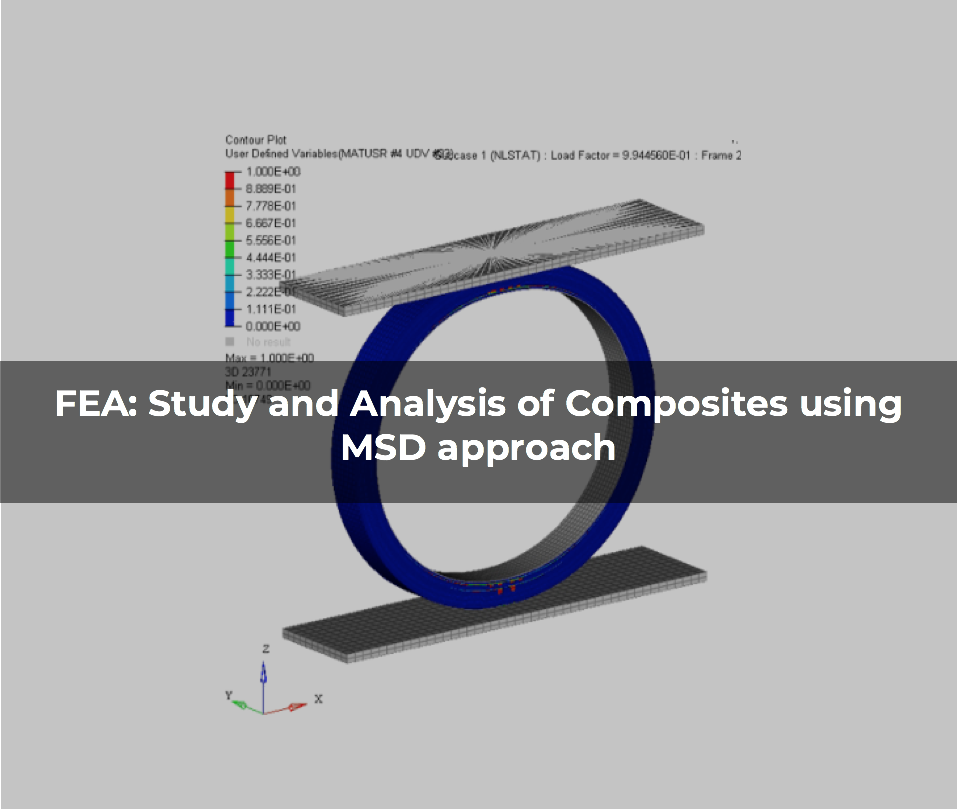

In the study of composites materials, a FE model is developed of a single phase material by modelling the properties at ply level. For obtaining a proper modelling of the individual ply, a good understanding of the material behaviour is important. In order to investigate the material stiffness and strength, a multiscale modelling approach was used.