Testing

Designing and developing highly innovative products is not a constant process. There are a lot of iteration steps to be made before the final product is ready for production. The production and testing facilities at ALE enable us to rapidly perform these steps. Quick prototyping and testing shortens the overall time-to-market.

ALE is unique in its pressure vessel testing facilities. We are equipped to perform almost all necessary certification tests according to the composite pressure vessel regulations R67-01 (automotive use), EN14427 (domestic use), and EN12245 (other applications).

For mechanical testing facilities, ALE works in close conjunction with the Delft University of Technology where over 1000 square meters of laboratory and production space is located.

Hydraulic Cyclic Test

– Maximum test pressure: 200 bars

– Capable of cycling up to 5 test samples at a time

– 24/7 continuous operation

– Automated testing

– Remote control and progress tracking from external location

– Optional temperature control for test sample (heating or cooling)

Pneumatic Pressure Test

– Maximum Pressure 60 bar

– Optional leakage testing

– Remote control and progress tracking from external location

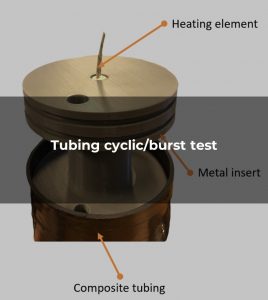

Tubing cyclic/burst test

– Custom tube diameters and lengths are available

– Provides seal without risk of damaging the test sample

– Higher safety due to smaller liquid volume

– Heating element can provide temperatures up to 500 degrees Celsius

– Cooling possible down to -20 C

– Optional strain gauges

Hydraulic Burst Test

– Maximum test pressure: 2800 bars

– Adjustable pressure gradient

– Remote control and progress tracking from external location

– Automated testing

– Optional temperature control for test sample (heating or cooling)

– Three machines available dependent on test requirements

Material tests form an essential part of a quality control program and are essential for validation of material and/or structural models. ALE is specialized in tests on fibre reinforced plastics, but can also offer tests on other materials.

Testing of bulk materials or the laminates you produce can provide the information required to consistently produce high quality products. Improved customer confidence and efficient troubleshooting can be further benefits of implementing a well-structured quality control system.

ALE is one of the few companies in the Netherlands that has experience in testing composite materials. We can help you with:

-

Implementing your own quality control system (if you don’t already have one)

-

Development of detailed material models

-

Development of detailed validated (Finite Element) models of the complete test set-up

Classification approval

Some of your clients may require approval by a classification society such as ABS, DNV or Lloyds Register. The society will normally require materials testing to be carried out on a calibrated testing facility. We have experience in dealing with these societies.

Sample preparation

ALE can prepare test specimens from test panels or material samples that you provide. Alternatively we can provide advice to those who wish to prepare their own samples.

Facilities

ALE offers a broad range of tests for fibre reinforced plastics. A number of these tests are carried out in-house and others are done at facilities of partners such as Delft University of Technology.

A selection of the tests which we can offer:

-

Tensile tests and compression (ASTM D3039 / ASTM D695): range: 10kN – 1000kN

-

Three-point and four-point bending (ASTM D790 / ASTM C393 / ASTM D2344 / ISO 15114)

-

Fiber content (ASTM D2584)

-

Void content (ASTM D2734)

-

Glass transition temperature (ASTM D3418)

-

Creep

-

Fatigue

-

Hardness measurement (polymers and metals)

-

Climate tests

-

Impact

-

Extreme temperature

-

Electron microscopy

-

Microscopy or non-destructive testing of e.g. laminates through a C-scan

-

Cut resistance testing of rubber materials based on ASTM F1790 / ISO 13997 / EN 388

On request, any test can be executed according to customer requirements. For information regarding these, or other tests, please contact us directly.

Deliverables

ALE will deliver a comprehensive report that conforms to the applicable test standard with each series of tests. This implies that not only the test results are provided but most important: the interpretation.

The report typically includes a detailed description of the test procedure, graphic and numerical results, calculations of material properties and a discussion of the failure modes with accompanying photographs.

ALE is unique in its pressure vessel testing facilities due to our revolutionary LoW8 technology. We are equipped to perform almost all necessary certification tests according to the composite pressure vessel regulations R67-01 (automotive use), EN14427 (domestic use), and EN12245 (other applications). More information about ALE’s patented Dry Filament Winding can be found at low8.com. This site is dedicated to all of our pressure vessel activities.

Pressure Vessel Testing

ALE has developed the revolutionary LoW8 cylinder for storage of LPG and other gases. For this Type IV composite cylinder 3 standards are applicable:

-

EN 14427: LPG equipment and accessories – Transportable refillable fully wrapped composite cylinders for LPG – Design and construction

-

EN 12245: Transportable gas cylinders – Fully wrapped composite cylinders

-

ISO 11119-3: Gas cylinders of composite construction – Specification and test methods Part 3: Fully wrapped fibre reinforced composite gas cylinders with non-load-sharing metallic or non-metallic liners

A Type Approval has been obtained for the LoW8 cylinder for EN 14427 (see low8.com).

What can ALE offer?

ALE has the knowledge, expertise and test facilities for carrying out tests on cylinders according to the standards EN 14427, EN12245 and ISO11119-3. We do not use the facilities exclusively for our own cylinder. Amongst others we can offer you the following tests:

-

Burst test

-

Cyclic test

-

(Hydraulic) proof test

-

Artificial ageing test

-

Drop test

-

Permeability test

-

Material testing

-

Flawed cylinder test

-

High velocity impact test