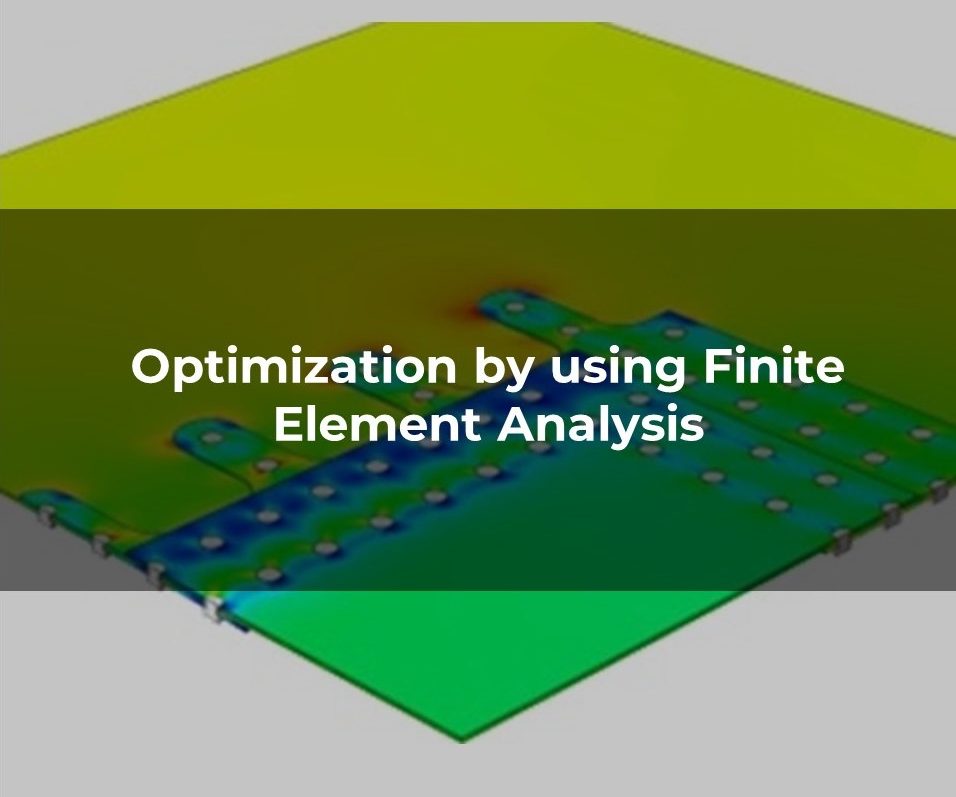

In a project for the aircraft industry, ALE has optimised the fatigue life of finger doubler repairs. External repair doublers are used to repair damaged aircraft skin panels. For the particular case of fibre-metal laminate skin, fatigue cracks occur in the skin underneath the repair doubler. This leads to inspection problems, which can be avoided if finger doubler repairs are used.

Finite Element (FE) analysis was used to evaluate peak stress for a given design. The FE model is set-up parametrically, such that the pre-processing, analysis and post-processing is fully automated, based on only the design parameters.

From the optimization, a finger doubler design was found, not only avoiding the inspection problems of the reference design, but also having an improved fatigue life and reduced mass.

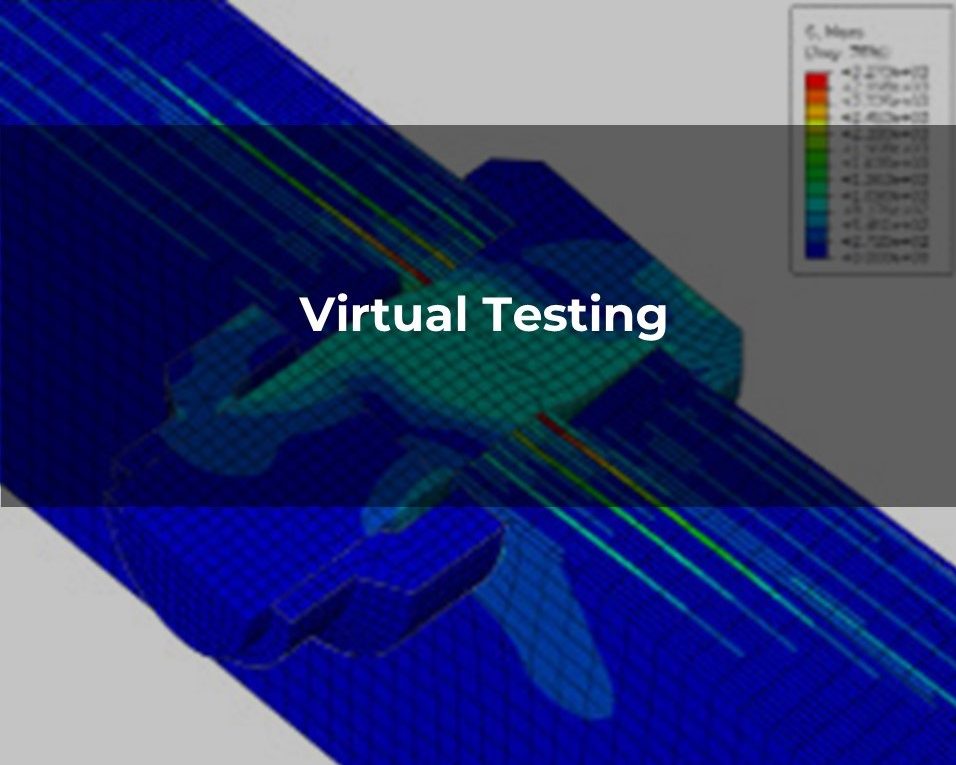

Shear pull tests were performed on simple bolted composite specimens, to be used as input for non-linear finite element modeling of typical skin to structure connections under crash or impact loads as part of an aircraft testing program. The aim of the project was to create finite element models and perform accurate simulations of the experiments.

In order to speed up the process of validating a large number of joints, differing in the type of bolt, lay-up, thickness and material, an ABAQUS plugin was created by ALE written in Python. The plugin generates a fully working ABAQUS model, based on dimensions and properties specified by the user via a simple Graphical User Interface.

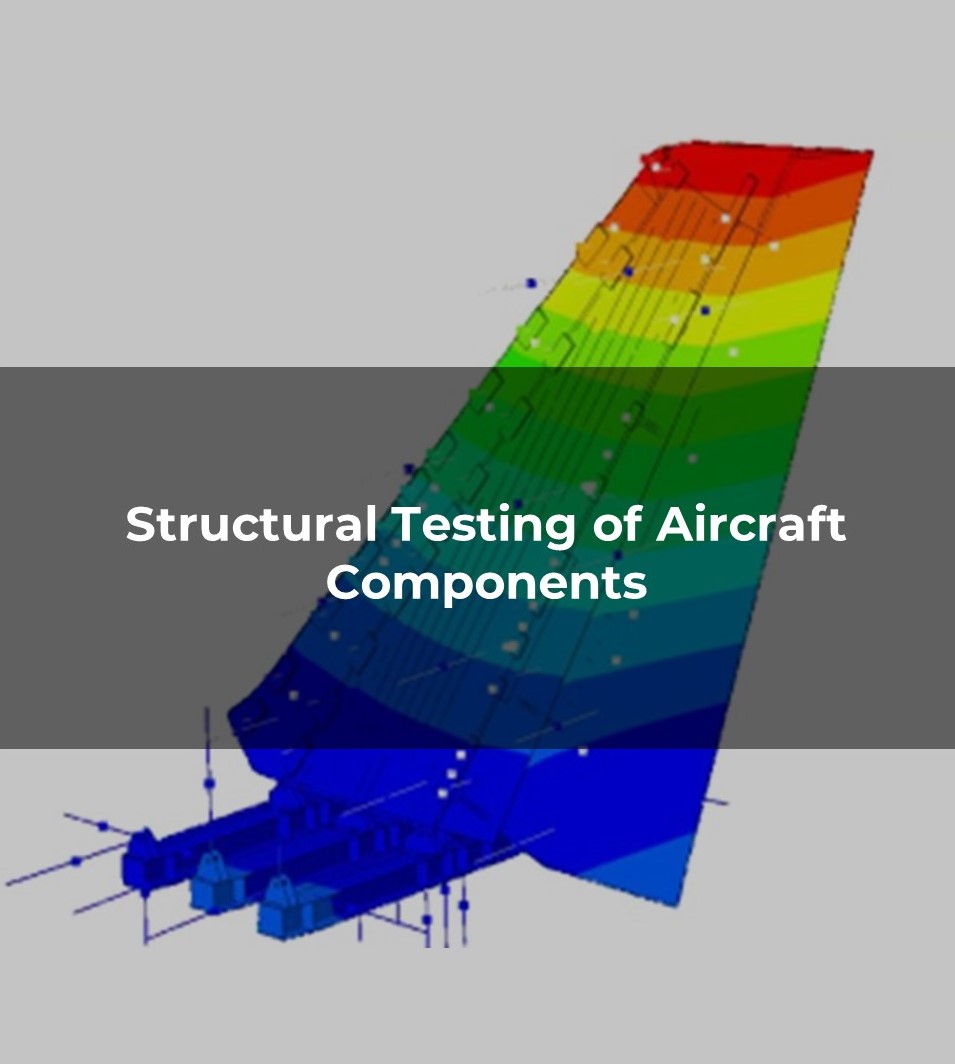

Structural testing of aircraft components is an essential part in the development of aircraft. To limit the number of tests and consequently cost, reliable Finite Element (FE) models to predict the test results are extremely important. For a test program on Vertical Tail Planes (VTP) ALE has developed a FE model of the VTP and the test rig.

The model has been successfully used to predict the response of the test. With the predictions, undesirable damage can be avoided and acceptable load levels for the different load cases can be defined. In the end the FE model has been validated by the tests and is now used to analyse the behaviour of VTPs when subjected to a variety of load cases and structural modifications.